Established in 1995, Digital Matrix Corporation provides world-class precision electroforming & plating equipment, systems, specialty electronic components, and development/ consulting services to industry, governments, and universities in 24 countries.

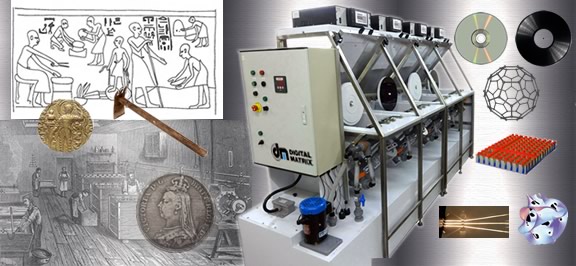

The art and science of applying transitional metals to objects through chemical deposition dates back thousands of years to the metallurgists, artisans and alchemists of ancient civilizations such as those in Egypt and India. Today, state-of-the-art electroforming & plating methods are used to “grow” precisely formed metal components essential to manufacturing optical discs, microchips, holographics, nanotechnology elements, vinyl recordings, fluidics and more.

See our EQUIPMENT CATALOG

Please contact us with your inquiry.

Media Disc Manufacturing

Vinyl Recordings The resurgence in demand for vinyl recordings in the music industry has led to a need for increased manufacturing capacity. Creating high-quality records for end-user sale calls for the production of a nickel-plated master disk used to press-out the finished product. Digital Matrix has available state-of-the-art plating systems designed to efficiently produce these “stampers.”

The resurgence in demand for vinyl recordings in the music industry has led to a need for increased manufacturing capacity. Creating high-quality records for end-user sale calls for the production of a nickel-plated master disk used to press-out the finished product. Digital Matrix has available state-of-the-art plating systems designed to efficiently produce these “stampers.”

See our selection of popular high-speed vinyl record plating and prep accessories

Contact us with your requirements.

Optical Disc Media Since 1995, Digital Matrix has been manufacturing electroforming systems (plating that separates from the mandrel) for the CD and DVD manufacturing industry world-wide. Digital Matrix has also been at the forefront in the development of stamper manufacturing for the new generation Blu-Ray and HD DVD formats.

Since 1995, Digital Matrix has been manufacturing electroforming systems (plating that separates from the mandrel) for the CD and DVD manufacturing industry world-wide. Digital Matrix has also been at the forefront in the development of stamper manufacturing for the new generation Blu-Ray and HD DVD formats.

Contact us with your requirements.

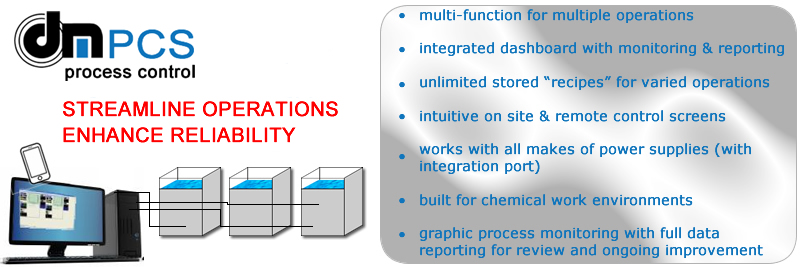

Digital Matrix’ newly released Advanced Process Control System is an affordable and complete software and processor product for managing multiple electrochemical processes for operational efficiency, reliability and safety. It is a standard feature with Digital Matrix systems but is available as a stand-alone package for existing tank and power systems. Please contact us with your inquiry.

MEMS | Microfluidics | Nano Tech

Digital Matrix has long been involved with plating for MEMS, microfluidics and Nano technology, both for industrial and research and development (R&D) applications utilizing both additive (plating) and subtractive (etching) electrochemical processes. Our equipment can be found not only in well-known manufacturing companies, but many of the leading research facilities and universities worldwide.

See our equipment catalog for sample plating tanks used for these applications.

Not ready for equipment purchase? Digital Matrix offers plating services for prototyping and small-scale production, including photo-lithography.

Contact us with your inquiry.

Holography & Flat Panel Display Applications

Digital Matrix is one of the leading manufacturers of electroplating equipment for the flat panel display and array structures industries. The range of models can support shims from 200 mm to 2.5 Meters with excellent control of thickness uniformity.

Digital Matrix is one of the leading manufacturers of electroplating equipment for the flat panel display and array structures industries. The range of models can support shims from 200 mm to 2.5 Meters with excellent control of thickness uniformity.

Digital Matrix offers a range of tank models that can be customized sizes to meet your requirements.

Example specifications sheet for 2-cell large shim electroforming system. (SA-1002)

Contact us with your inquiry.

Lens Manufacturing

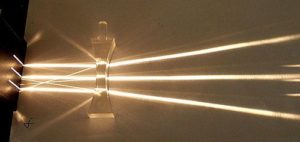

Precision lens-making is used across a broad range of industries – medical, automotive, gaming, and many more. Digital Matrix builds custom plating for the mold inserts used to replicate precise lens components.

Precision lens-making is used across a broad range of industries – medical, automotive, gaming, and many more. Digital Matrix builds custom plating for the mold inserts used to replicate precise lens components.

See our precision plating equipment catalog.

Contact us with your inquiry.

Prototyping & Production Services

Additive manufacturing through electroforming can bring many economic and quality-control benefits to your manufacturing process compared to other production methods such as 3-D printing, chemical etching, laser cutting or stamping. Electroforming provides a high-precision, atom-by-atom deposition to create critical components for state-of-the art equipment used in a wide array of devices for medical, optical, gaming, and many other industry applications.

Additive manufacturing through electroforming can bring many economic and quality-control benefits to your manufacturing process compared to other production methods such as 3-D printing, chemical etching, laser cutting or stamping. Electroforming provides a high-precision, atom-by-atom deposition to create critical components for state-of-the art equipment used in a wide array of devices for medical, optical, gaming, and many other industry applications.

We recognize that the introduction of in-house additive manufacturing equipment can represent a significant resource commitment, which is why we offer LIGA* prototyping services to help develop proof-of-concept samples, along with strategic planning to maximize your return on investment if you decide to go forward with equipment purchase. Depending on your requirements, we can also provide actual production runs on an outsource basis. Please contact us to start the conversation!

* LIGA is a German acronym used to refer to the processes of lithography, electroforming, and molding use to create microstructures.

Specialty Electronics | Software | Consulting

Digital Matrix offers built-to-order application-specific power supplies (rectifiers), as well as high-performance controllers for precise voltage regulation, durability in challenging plating environments, and reliability for all levels of production.

Digital Matrix offers built-to-order application-specific power supplies (rectifiers), as well as high-performance controllers for precise voltage regulation, durability in challenging plating environments, and reliability for all levels of production.

User-friendly touch-panels or remote PC apps provide easy process management through both firmware and customized software for specific application.

The Digital Matrix engineering team has been put to work on diverse projects such environmental control systems for skyscrapers, aviation prototyping, electronic toll collection systems, and much more. Activities can include development of proof-of-concept prototypes, advanced technical research and analysis, and integration of disparate process applications. Contact us with your inquiry.

Customers

We count these organizations and many others among our clients for both equipment and consulting services:

Contact Us

Digital Matrix Corporation

34 Sarah Drive, Suite B

Farmingdale, NY 11735 USA

(+1) 516.481.7990

Sales Inquiries ext. 103

Technical Support ext. 101

Admin. | Parts Orders ext. 102