Description

B5000 Specifications

Pump: Available in CPVC, polypropylene, PVDF (Kynar), and stainless steel as pump materials of construction. Standard internal shaft is made of 303 stainless steel covered with Teflon heat-shrink tubing. For solutions that aggressively attack stainless steel, a titanium-tip or Hastelloy-276C-alloy-tip shaft that threads onto the impeller is available on special-order basis. See “Construction Materials” tab for more information on material selection.

Flow Rate: 5000 gallons (19,000 liters) per hour at 60 Hz. A flow-rate reduction of about 18% is typical when operating at 50 Hz.

Pressure: 27 feet (8.2 meters) of head pressure.

Weight: About 29 pounds (13 kg) in CPVC, depending on pump body length

Motor: Epoxy coated, TEFC, Thermally Protected. Electrical cord is 12 feet long (3.6 meters). Select from the following motors:

(1) Single phase, 3/4 HP (560 watt), 115/230 V, 9.6/4.8 A, 60 Hz, 3450 RPM

(2) Single phase, 3/4 HP (560 watt), 110/220 V, 9.2/4.6 A, 50 Hz, 2850 rpm

(3) Three phase, 1 HP (760 watt), 220/460 V, 3.0/1.5 A, 60 Hz, 3450 RPM. (Note: There is an additional charge for three-phase motors).

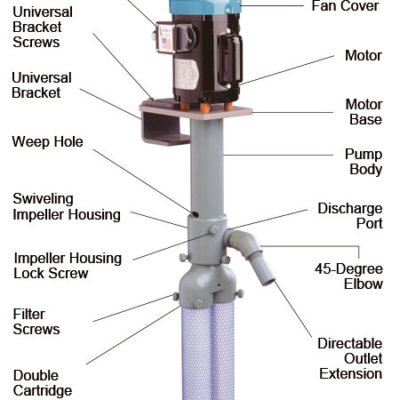

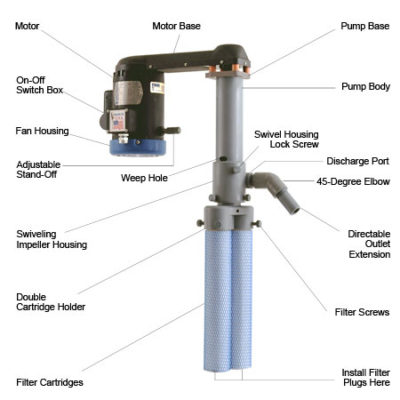

BX5000 Pump-Body Length

All Flo King pumps are manufactured in different pump-body lengths to accommodate the freeboard (distance from top of tank to solution surface) and, in many cases, tank depth. To ensure priming and proper operation, solution must be 4 inches (10 cm) or more above the Weep Hole on the BX5000 pump body. The Impeller is located just beneath the Weep Hole and must be submerged in solution for the pump to operate.

Specify length of pump body when ordering. If you are not sure of which length is required, please fill out our tank questionnaire and we will recommend a system.

Contruction Materials

General guidelines for selecting BX3000 and BX5000 pump material of construction are shown below.

Disclaimer: This is a general guide based on user operating experiences with Flo King Filter Systems. The information presented may not be suitable for every application.

CPVC as Pump Material of Construction

CPVC as Pump Material of Construction

CPVC (gray in color) is our standard, least-expensive, and by far the most popular pump material of construction for the BX3000 and BX5000. CPVC is generally recommended for neutral solutions and many acids at a wide range of temperatures.

CPVC is also often be used in mildly alkaline solutions at temperatures up to 160-180 (71 to 82 C). However, CPVC may become brittle, then crack and split, in some highly alkaline solutions, even at relatively low temperatures (examples: alkaline non-cyanide zinc or aggressive, highly caustic alkaline cleaners).

Typical CPVC applications include: nickel electroplating, acid copper plating, acid tin plating, acid zinc plating, chromating, decorative chrome plating, some hard chrome plating applications, lower-temperature electroless nickel plating (185 – 190 F, 85 – 89 C), passivating, pickling, rinsing, anodizing, low-temperature seals, mild alkaline cleaners. Many customers use CPVC in cyanide silver, cyanide copper and cyanide zinc, though some prefer polypro.

Polypropylene as Pump Material of Construction

Polypropylene (white in color) can also be used in neutral solutions and some acids at a wide range of temperatures.

Polypropylene is generally satisfactory for mild to moderately aggressive alkaline solutions at temperatures up to 160 – 170 F (70 – 77 C). However, at temperatures well above 170 F (77 C) or in highly concentrated, high-pH caustic solutions, polypropylene may swell, causing serious pump problems. In cases of aggressive caustics — especially at higher temperatures — only stainless steel pump construction is recommended.

Polypropylene is readily attacked by concentrated chromic acid and cannot be used in applications such as hard chrome plating or chromic acid anodizing.

Polypropylene costs about 10 percent more than CPVC for the BX3000.

Typical polypro applications include: alkaline non-cyanide zinc plating, zincating, electroless nickel up to about 194 F (90 C), gold, high-purity precious-metals plating processes, mild alkaline cleaners

Kynar (PVDF) as Pump Material of Construction

Kynar is a high-temperature plastic that can be used in neutral solutions up to about 215 F (105 C) and also in many acids at higher temperatures than CPVC can withstand.

However, like CPVC, Kynar is absolutely not recommended for highly aggressive alkaline solutions. It tends to become brittle, then crack and split in aggressive caustics.

Typical Kynar applications include: hard chrome plating, chromic acid etches, chromic acid anodizing, electroless nickel solutions well above 190 F (88 C), high-temperature seals following anodizing (sometimes up to 212 F, 100 C), and high-temperature sulfuric/phosphoric acid electroplating solutions.

Kynar is expensive — from 50 to 65 percent more than CPVC and 40-55 percent more than polypro for the BX3000 and BX5000, depending on required accessories.

Stainless Steel as Pump Material of Construction

Stainless steel (SS) is the material of choice for highly aggressive alkaline solutions at high temperatures — typically from 180 to 200 F (70 to 93 C).

Typical SS applications include: caustic high-pH cleaners, caustic strippers, caustic permanganate solutions, and black oxide (up to about 205 F, 96 C).

The BX3000 and BX5000 are available in stainless steel, but only in the 14-inch-long pump-body length. Depending on accessories required, the SS BX3000 and SS BX5000 cost about 135 to 155 percent more than CPVC, 125 to 145 percent more than polypro, and 60 percent more than Kynar.

Most customers use SS pumps strictly for recirculation (without filter cartridge attached).

SELECT MATERIAL BY METAL-FINISHING PROCESS

There are many solutions in which the Flo King system is effective.

Click this link to see pump material recommendations for many popular electroplating and other metal-finishing applications.

INTERNAL METAL-SHAFT MATERIALS FOR BX3000 & BX5000

Unless otherwise specified, all Flo King pumps have an internal shaft made of 303 stainless-steel covered with Teflon heat-shrink tubing. In most cases, this works well, but when there is a failure, it almost always occurs when aggressive acids attack the SS Shaft where the Impeller screws onto the Shaft threads. This may happen because of (1) pinholes or other imperfections that develop in the Teflon coating, (2) wear and tear over time, or (3) objects that are sucked into the pump and damage the Teflon heat-shrink tubing. Caution: If using the pump strictly for recirculation (without filter cartridge attached), always install a Pump Strainer Adapter (PSA) to protect the Impeller, Shaft, and Teflon heat-shrink tubing from damage due to any foreign objects that might be in solution. See this link for PSA photo.

Unless otherwise specified, all Flo King pumps have an internal shaft made of 303 stainless-steel covered with Teflon heat-shrink tubing. In most cases, this works well, but when there is a failure, it almost always occurs when aggressive acids attack the SS Shaft where the Impeller screws onto the Shaft threads. This may happen because of (1) pinholes or other imperfections that develop in the Teflon coating, (2) wear and tear over time, or (3) objects that are sucked into the pump and damage the Teflon heat-shrink tubing. Caution: If using the pump strictly for recirculation (without filter cartridge attached), always install a Pump Strainer Adapter (PSA) to protect the Impeller, Shaft, and Teflon heat-shrink tubing from damage due to any foreign objects that might be in solution. See this link for PSA photo.

When to Consider Alternative Internal-Shaft Materials: If a solution is known to aggressively attack stainless steel, an internal titanium-tip or Hastelloy-tip Shaft is strongly recommended as a precaution for the BX3000 and BX5000. One end of the tip is threaded onto the SS shaft and the other end onto the Impeller to provide additional protection. All Shafts are covered with Teflon Heat-Shrink Tubing.

• Some Titanium-Tip Internal-Shaft Applications: Sulfuric acid anodizing, acid copper plating (sulfuric acid), hard chrome plating (non-fluoride type), chromic acid etch.

• Hastelloy-Tip Internal-Shaft Applications: Hastelloy C276 is a nickel-chrome-molybdenum-tungsten alloy that has better resistance to fluorides than does titanium. It is the customer’s responsibility to determine if the solution attacks both stainless steel and titanium. If you are unsure if Hastelloy is needed for your application, we suggest you contact the chemical supplier for advice.

OTHER SOURCES OF MATERIAL INFORMATION

There are many Chemical Resistance Charts available on the internet. We encourage you to research those charts for plastic and metal compatibility information if you do not find what you need here.

CPVC as Pump Material of Construction

CPVC as Pump Material of Construction Unless otherwise specified, all Flo King pumps have an internal shaft made of 303 stainless-steel covered with Teflon heat-shrink tubing. In most cases, this works well, but when there is a failure, it almost always occurs when aggressive acids attack the SS Shaft where the Impeller screws onto the Shaft threads. This may happen because of (1) pinholes or other imperfections that develop in the Teflon coating, (2) wear and tear over time, or (3) objects that are sucked into the pump and damage the Teflon heat-shrink tubing. Caution: If using the pump strictly for recirculation (without filter cartridge attached), always install a Pump Strainer Adapter (PSA) to protect the Impeller, Shaft, and Teflon heat-shrink tubing from damage due to any foreign objects that might be in solution.

Unless otherwise specified, all Flo King pumps have an internal shaft made of 303 stainless-steel covered with Teflon heat-shrink tubing. In most cases, this works well, but when there is a failure, it almost always occurs when aggressive acids attack the SS Shaft where the Impeller screws onto the Shaft threads. This may happen because of (1) pinholes or other imperfections that develop in the Teflon coating, (2) wear and tear over time, or (3) objects that are sucked into the pump and damage the Teflon heat-shrink tubing. Caution: If using the pump strictly for recirculation (without filter cartridge attached), always install a Pump Strainer Adapter (PSA) to protect the Impeller, Shaft, and Teflon heat-shrink tubing from damage due to any foreign objects that might be in solution.